Selecting the right type of packaging materials ensures your product reaches its destination intact. This makes it important to understand the differences between steel strapping and polyester strapping properties, to make certain you are using the product best suited to your application.

Understanding The Differences Between Steel and Polyester Strapping

Most agree that steel strapping is stronger but polyester strapping is more versatile, this means that there are instances when one type of strapping will be better suited than the other.

Your first consideration is to ensure your strapping has the strength to withstand the pressure or forces it will be subjected to during use.

Not only should you consider the load weight and size but also corrosives, moisture and temperature change your load may be exposed to.

Learn more about the differences between steel and polyester strapping below.

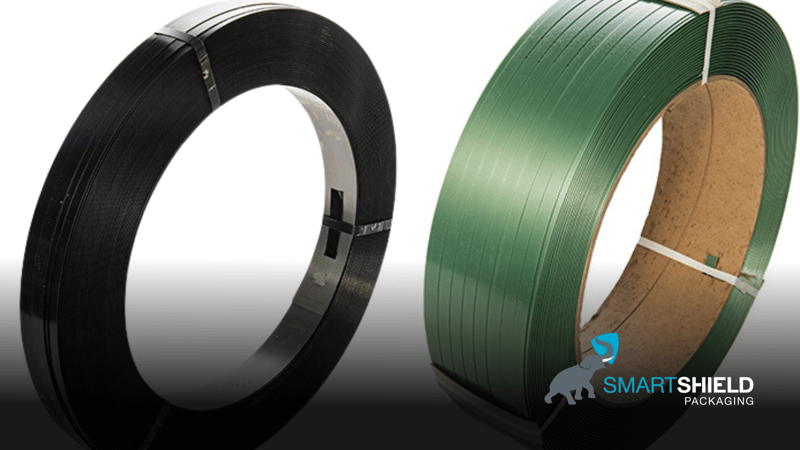

Steel Strapping

Steel strapping is the strongest strapping material, the ultimate choice for heavy loads or sharp-edged material shipments that cannot, or do not need to be compressed.

As steel strapping retains its tension it is ideal for keeping stable loads secure for long periods of time. It is resistant to moisture and extreme temperature changes, and can withstand prolonged exposure to UV light.

However, untreated steel strapping may rust in outdoor environments, leaving stains on your product.

- Width: Steel strapping comes in a variety of widths, from 3/8 inch to 1-1/4 inch.

- Thickness: The thickness of the steel can also vary. For the strongest option, select the thickest strapping. On average, steel strapping thicknesses range between 0.020 inch and 0.035 inch.

- Elasticity: Since steel is a metal, it has low elasticity. This means that it won’t stretch or break. Ultimately, steel strapping retains good tension, offering sturdy, stable load support. However, with no elasticity steel strapping is not the ideal packaging solution for items that expand or contract when exposed to moisture.

- Strength: High strength steel strapping has the highest tensile strength, meaning it is perfect for sharp edged product or those extra heavy loads.

- Cost: Steel is a sturdy choice, but can also be more costly than polyester as the price of metal fluctuates. Steel strapping is a heavy material sold in smaller rolls than polyester, meaning a larger quantity of steel strap coils are required to acquire the same total length of strapping.

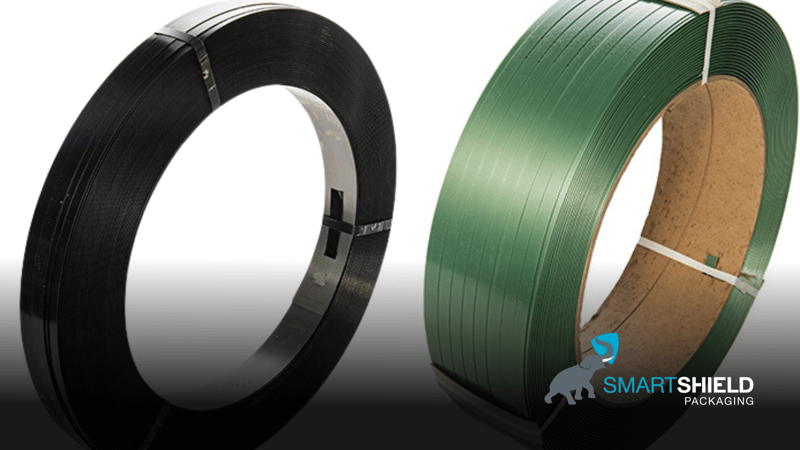

Polyester Strapping

Polyester strapping is a versatile material, a better choice than steel when your package requires being compressed, or when it has the potential to expand, contract, or settle.

This is a way of saying that polyester material is elastic, so it can adjust as your shipment adjusts during transit.

PET strapping is also resistant to corrosives and moisture, it will not stain your product.

- Width: Polyester strapping most commonly comes in 3/8 inch – 5/8 inch

- Thickness: Polyester strapping tends to be thicker than steel strapping with the average thickness ranging from 0.02 inch - 0.05 inch. This thicker material gives polyester strapping the strength required to be a popular alternative to steel strapping, except for those extra heavy load applications.

- Elasticity: Polyester has a higher elasticity than metal. This means that polyester is able to stretch and give if your product shifts, expands or contracts during transit, reducing the risk of damaging your product. With low elongation properties it offers an impressive retained tension period, and the superior recovery properties of polyester strapping allows it to absorb heavy impacts without breaking.

- Cost: Polyester is a more economical choice compared with steel, with longer roll lengths it also means fewer roll changes and warehouse space required.

In Conclusion:

Overall, unless you have a large or extra heavy load, or sharp-edged product that requires sturdy metal straps, polyester strapping is the ultimate packaging option. Save on the cost of materials and labor, and increase productivity with longer rolls.

Polyester strap is a recyclable material making it more environmentally friendly, coils are lighter so more user friendly and softer material reduces potential damage to product or injury to the user.

However, there are applications where steel is the most suitable option; though polyester has impressively retained tension compared with polypropylene strapping, unlike steel, over a long period of time, polyester does begin to lose its tension, also unlike steel, its performance degrades with large amounts of UV exposure or extreme temperature changes.

| STRAP TYPE |

SUGGESTED USE |

| Polypropylene Strapping |

Light – Medium Duty Application |

| Polyester Strapping |

Medium – Heavy Duty Application |

| Steel Strapping |

Heavy – Extra Heavy Duty Application |

Remember: Strapping is applied using tension, therefore when removing strapping materials use caution, eye protection is recommended.

We hope this post helped explain the difference between steel and polyester strapping material. Our team are here to help you select the best packaging materials and equipment for your requirements, at SmartShield we strive to make our customers smile with packaging done right. Click HERE to contact us.

Related articles: