Wood packaging costs are constantly fluctuating. If you're seeking ways to trim your business expenses without compromising quality, wood packaging alternatives can be a game-changer.

Discover how you can cut costs with packaging options beyond wood - from the versatility of cardboard to the strength of hybrid designs. Each packaging design has its own unique advantages to enhance your packaging strategy while keeping your budget in check.

Why is Wood Packaging so Expensive?

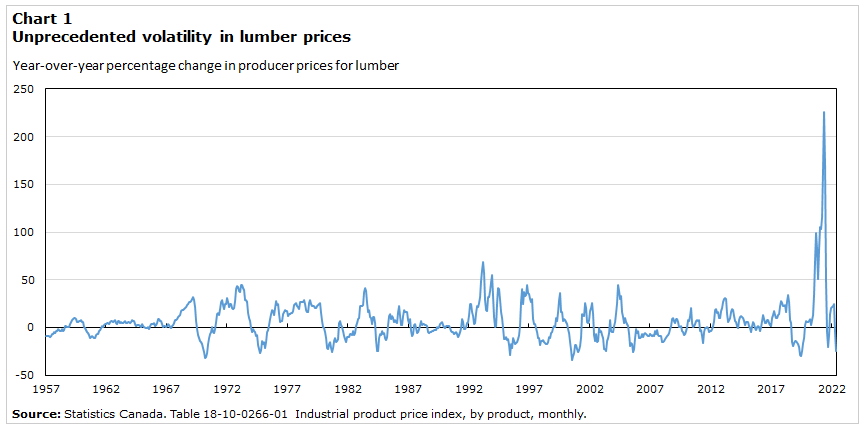

The Canadian lumber market experiences significant fluctuations, impacting the cost of wood packaging. As a major supplier of lumber, Canada's pricing trends play a crucial role in determining global wood packaging costs. These fluctuations are often a result of various factors, including trade policies, environmental regulations, and market demand.

One of the most noticeable effects is the rising cost of wood packaging. As lumber prices surge, sometimes as high as 200%, so does the expense of producing wooden crates, pallets, and cages.

This increase is not just about higher costs; it also brings a level of unpredictability to budgeting for packaging needs. Businesses that rely heavily on wood packaging are finding it increasingly challenging to forecast expenses and maintain consistent profit margins.

Reasons Why Businesses Use Wood Packaging

Benefits of Wood Packaging

- Durability: Wood is robust and can withstand heavy loads, making it ideal for transporting bulky or heavy items.

- Stackability: Wooden crates and pallets can be easily stacked, optimizing space in storage and during transportation.

- Customizability: Wood packaging can be tailored to specific dimensions and shapes, accommodating a wide range of products.

- Reusable and Repairable: Wooden packaging can often be reused and repaired, extending its lifecycle.

- Load Security: Offers excellent security for goods, especially in transit, due to its sturdy nature.

Disadvantages of Wood Packaging

- Cost Fluctuations: Prices are subject to fluctuations, particularly influenced by the lumber market, as seen in Canada.

- Weight: Wooden packaging is heavier than alternatives, leading to higher transportation costs.

- Environmental Impact: Wood sourcing can contribute to deforestation and carries a higher carbon footprint.

- Storage Space: Requires more storage space, both when in use and when idle, compared to more compact alternatives.

- Maintenance: Susceptible to moisture damage, pests, and rot, necessitating regular maintenance, treatment and proper disposal.

Cost-Saving Wood Packaging Alternatives

The shift from traditional wood packaging to innovative alternatives can offer more than cost savings. Here’s a closer look at each alternative and the compelling reasons for their adoption.

1. Heavy Duty Cardboard

Heavy Duty Cardboard is a robust, reinforced cardboard form designed for industrial use. It's engineered to withstand greater weights and stresses than standard cardboard, making it suitable for various packaging needs.

- Lightweight Yet Sturdy: Heavy Duty Cardboard balances strength and weight. It's significantly lighter than wood, reducing shipping costs, but still strong enough to protect products during transit.

- Reusable: When designed right, this wood packaging alternative has a relatively long lifespan.

- Flexible Design Options: This material can be easily shaped and cut to fit various product sizes and shapes, offering greater customization than standard wood packaging.

- Cost-Effective: Heavy Duty Cardboard is generally more affordable than wood, both in terms of material costs and shipping expenses, thanks to its lighter weight.

- Eco-Friendly: Being recyclable, it aligns with sustainable practices, reducing the environmental impact compared to using new or treated wood.

Heavy duty cardboard is one of the mort popular wood packaging alternatives. It offers significant cost savings in terms of both material and shipping expenses due to its lighter weight.

Related article: How to Choose the Right Cardboard Box Material for Your Application

2. Chip Board Corners

Chip Board Corners are sturdy, angular pieces made from compressed chipboard. They are designed to protect the corners and edges of packaged products, which are most prone to damage during transit.

- Enhanced Protection: Chipboard Corners are designed to protect the corners and edges of products, which are often the most vulnerable parts during shipping.

- Versatility: These corners can be used alongside other materials, like heavy-duty cardboard, to create a hybrid solution that balances protection and cost.

- Lightweight and Compact: They take up minimal space and add negligible weight to packaging, helping to keep shipping costs low.

Go with chipboard corners if you want to enhance your products' protection without increasing packaging weight. These are a cost-effective solution for reinforcing package corners while adding minimal weight and helping you save on shipping costs.

3. Honeycomb Packaging

Honeycomb packaging consists of a unique honeycomb-shaped cellular structure sandwiched between two flat panels. This design offers incredible strength and rigidity while remaining lightweight.

- Superior Strength-to-Weight Ratio: Honeycomb packaging is renowned for its exceptional strength without the bulkiness of wood, ideal for heavy or delicate items.

- Shock Absorption: Its unique structure provides excellent cushioning against impacts and better protection of products during transportation.

- Customizable and Flexible: It can be easily cut and shaped to fit specific packaging needs, offering versatility similar to cardboard.

- Environmentally Friendly: Often made from recycled paper products, honeycomb panelling is a sustainable option that contributes to waste reduction.

This alternative is perfect for businesses needing a high strength-to-weight ratio in their packaging. Honeycomb packaging’s shock-absorbing properties make it ideal for protecting fragile or heavy items.

4. Plastic Pallets

Plastic packaging solutions are often controversial because they’re made from non-renewable petroleum. However, plastic pallets are recyclable. When plastic is made entirely from HDPE, it can be recycled – and reused – repeatedly without losing its key properties.

- Water and chemical resistance: Plastic pallets are durable, non-porous materials; they are resistant to water and most chemicals, making them easy to clean or sterilize.

- Hygienic: These pallets are ideal for businesses handling fresh and frozen foods or pharmaceutical products, where hygiene is paramount.

- Reusable: Their design allows them to be reused many times, often outlasting wooden pallets significantly.

5. Hybrid Packaging Solutions

Hybrid packaging involves combining different packaging materials to leverage the strengths of each. This can include a mix of cardboard, plastic, wood, and other materials, depending on the specific requirements of the product being packaged.

Every business is unique, that’s why a hybrid solution is often the best approach to ensure your products are packaged right.

Need a custom packaging solution?

At SmartShield, we often combine materials to create a custom packaging solution for the exact needs of a product. Whether that's enhanced strength, reduced weight, or improved sustainability — we can help you fine-tune your packaging strategy to meet both your logistical requirements and financial goals.