Tooling and artwork fees are required when higher volumes of packaging are required and they help to bring the overall cost of the packaging down by increasing efficiency. Similar to the way that prototypes of products are built differently to production versions, low volumes of packaging are built differently to production runs.

Utilizing custom tooling also provides you with a more unique package which can ensure your products are packaged appropriately and also provide your customer with a better unpacking experience, always remember your packaging is the first thing a customer sees!

Understanding tooling, artwork & setup fees

Tooling fees

The most common type of tooling you will see on your quote is for steel rule dies. Steel rule dies are used to stamp out shapes from raw materials such as cardboard, chipboard or foam, often these dies can be set up to cut out multiple pieces at a time to help improve efficiency on high volume jobs.

Flatbed Steel rule dies are commonly used to die cut foam, these dies are capable of cutting up to 4” of foam! You can tell if foam has been die cut as the cut sides of the material will have a slight curvature to them from where the foam compressed.

Flatbed and rotary dies are used when die cutting cardboard and chipboard materials, these dies are mounted to automated machines that are then able to produce consistent products at high speed, there is the initial set up cost of the tool but for high volume jobs they pay for themselves quickly!

You can tell if cardboard has been die cut as the edges of the board are compressed from being stamped out of a sheet.

Steel rule dies are mainly used with cardboard and chipboard to produce a variety of mailer types, complex inserts, to put hand holes, and whenever litho printing is required. Steel rule dies are usually used with foam when high volumes are required, when shapes need to be cut out of the middle of blocks, and when tolerances are not too tight.

The cost of tooling is determined by the size and complexity of the tool, generally ranging from $150 to up to $1500.

Artwork Fees

Print plates are required when you need to apply details to the outside of your box this could include company logos, fragile symbols, pictures of the product you are packing and much more!

Print plates are used in a flexographic printing process which in its simplest of explanations means the print plates work as large stamps to apply ink to boxes. When multiple colors are required you need to have one print plate for each color.

Print plates are mounted to cylinders and as the boxes pass underneath the print is applied, this type of printing is great for high volume production and provides a very consistent output and quality of print, print plates like this can do surprisingly complex and detailed printing.

One thing to remember when investing in this tooling is if you just want your print on 2 sides of the box and in one color, you can use the same print plate on multiple sizes of box!

It is important to remember that this type of printing doesn’t provide the level of detail you often see in retail packaging where the packages are generally litho printed or digitally printed.

The cost of print plates varies depending on the complexity of the print but costs would generally range from $150 to $2000.

Set Up Fees: A One-Time Investment

Set up fees, like print plates and tooling, are a one time fee. This fee covers for the cost of creating CNC files for production.

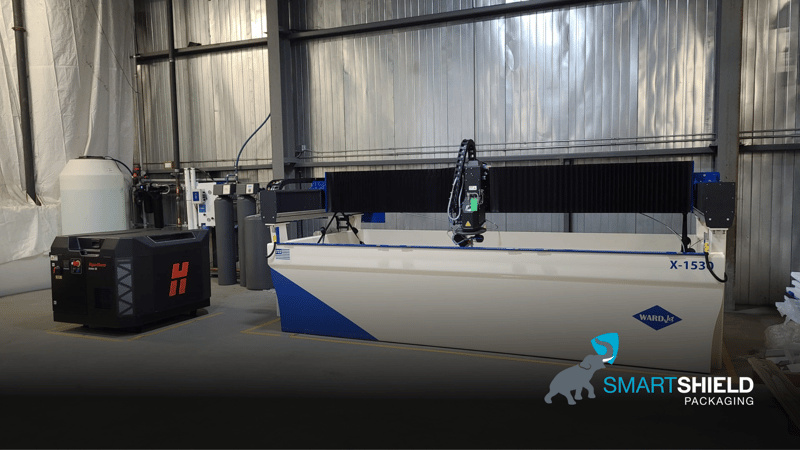

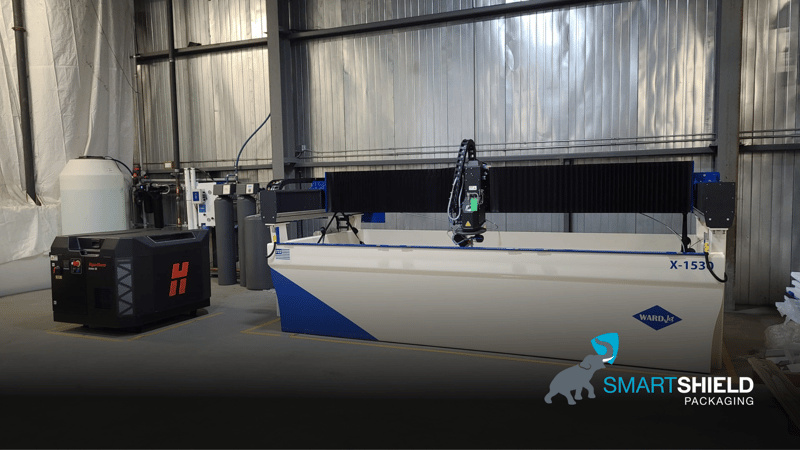

When materials such as foam, cardboard or chipboard require CNC routering, CNC knife cutting, or waterjet cutting there is a fee associated with the creation of these files.

Generally speaking these fees apply to jobs that are lower volume or require very tight tolerances. Set up fees generally range from $50 to $200.

Are there ways around these fees?

Yes there are! For tooling, anything that is die cut can be CNC cut but this does increase the unit cost so at a certain quantity it always makes sense to invest in the tooling.

If the tooling is associated with the outer box you can change the design of the box to a standard carton and this will also mean tooling is not required.

To get around the cost of print plates boxes can be digitally printed but this is much more expensive so again there is always a certain quantity where it makes sense to invest in the print plates.

Labeling boxes manually is another option to prevent having to invest in print plates. Set up fees are more tricky to avoid and would require that you utilize straight materials or creating another solution altogether.

Contact us for more details!